How-To Guides about Auto Maintenance & Repairs

how to

How to Operate a Car Jack

how to

How to Replace a Door Lock Actuator on a Ford Explorer

how to

How to Replace Steel Brake Lines

Featured On WonderHowTo:

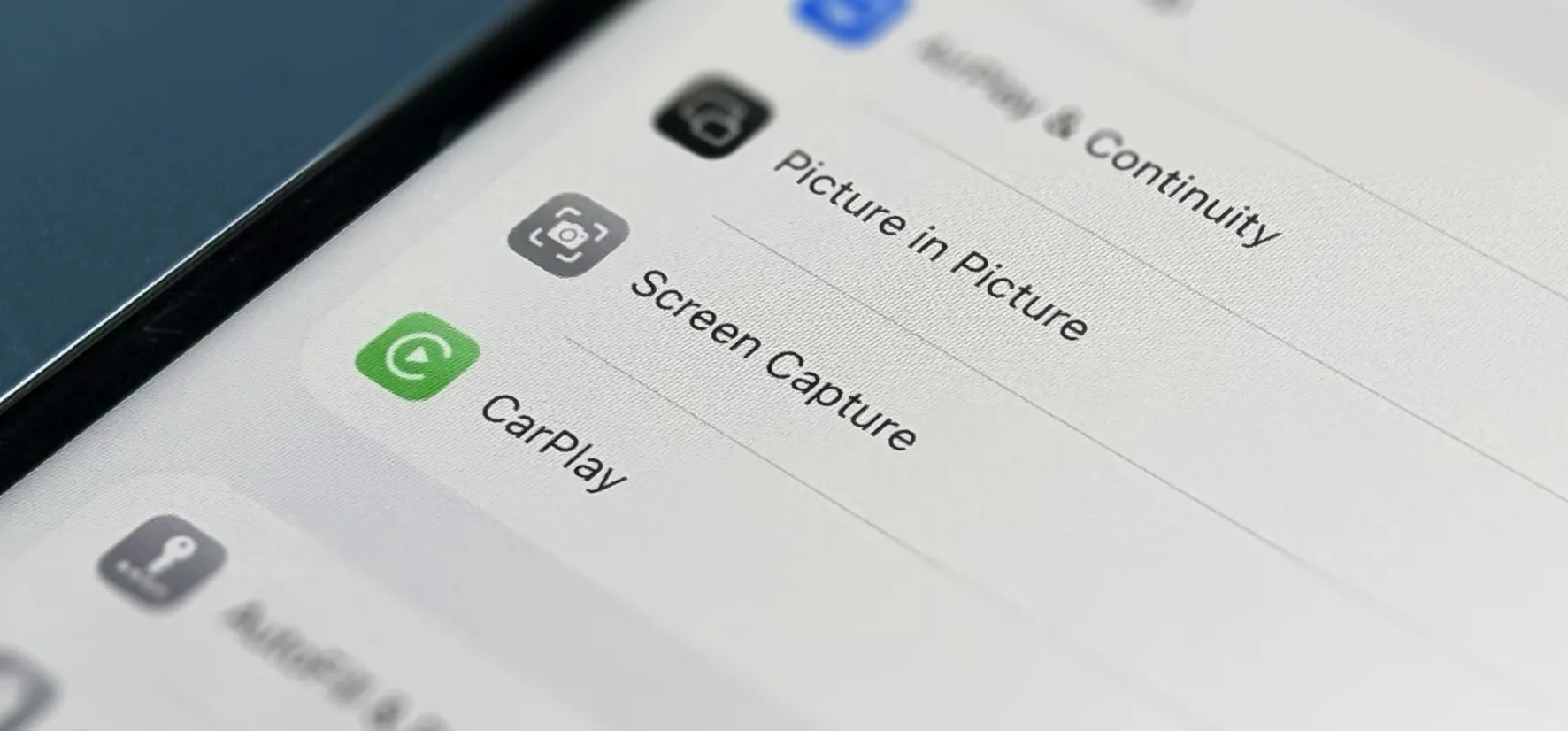

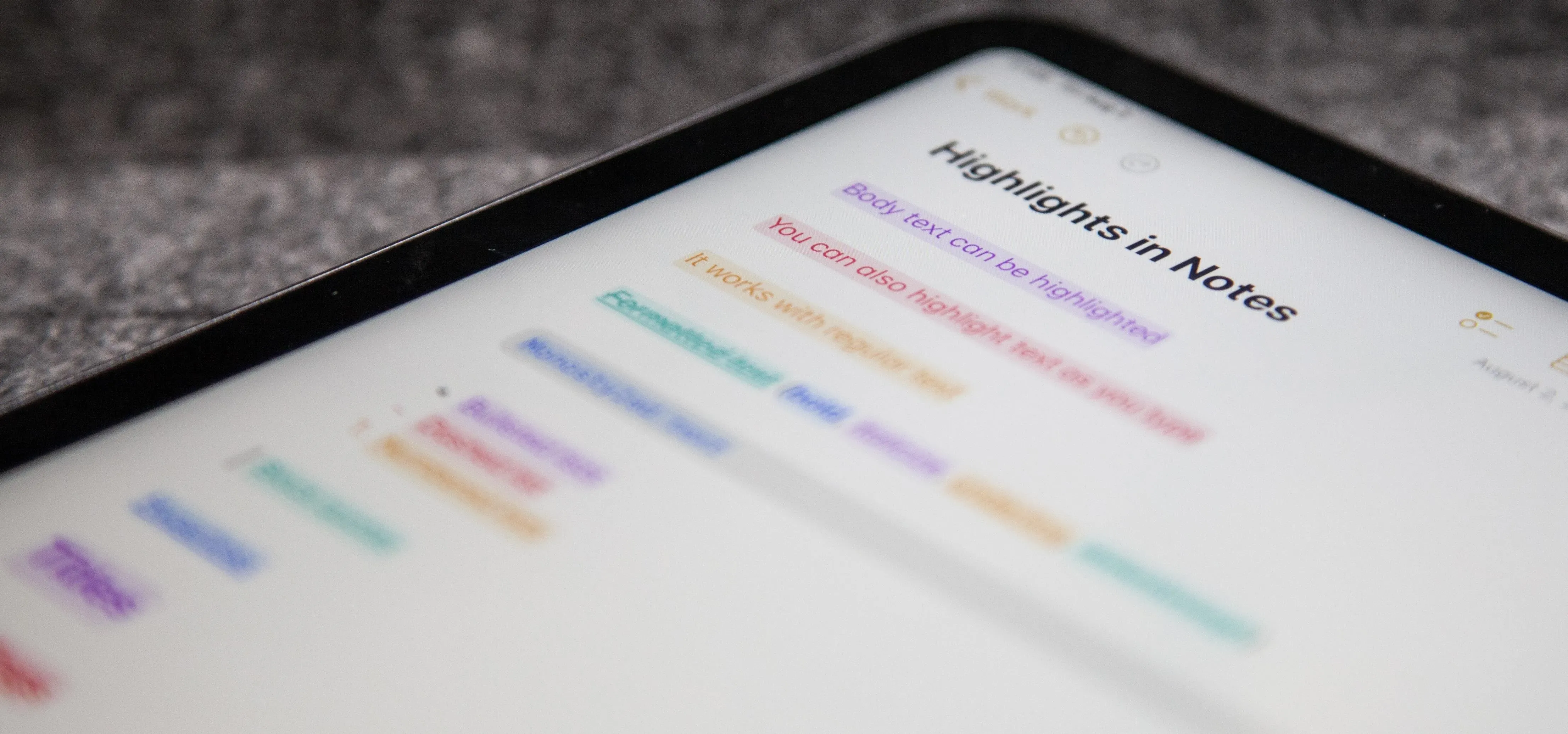

Productivity & Shortcuts

Featured On WonderHowTo:

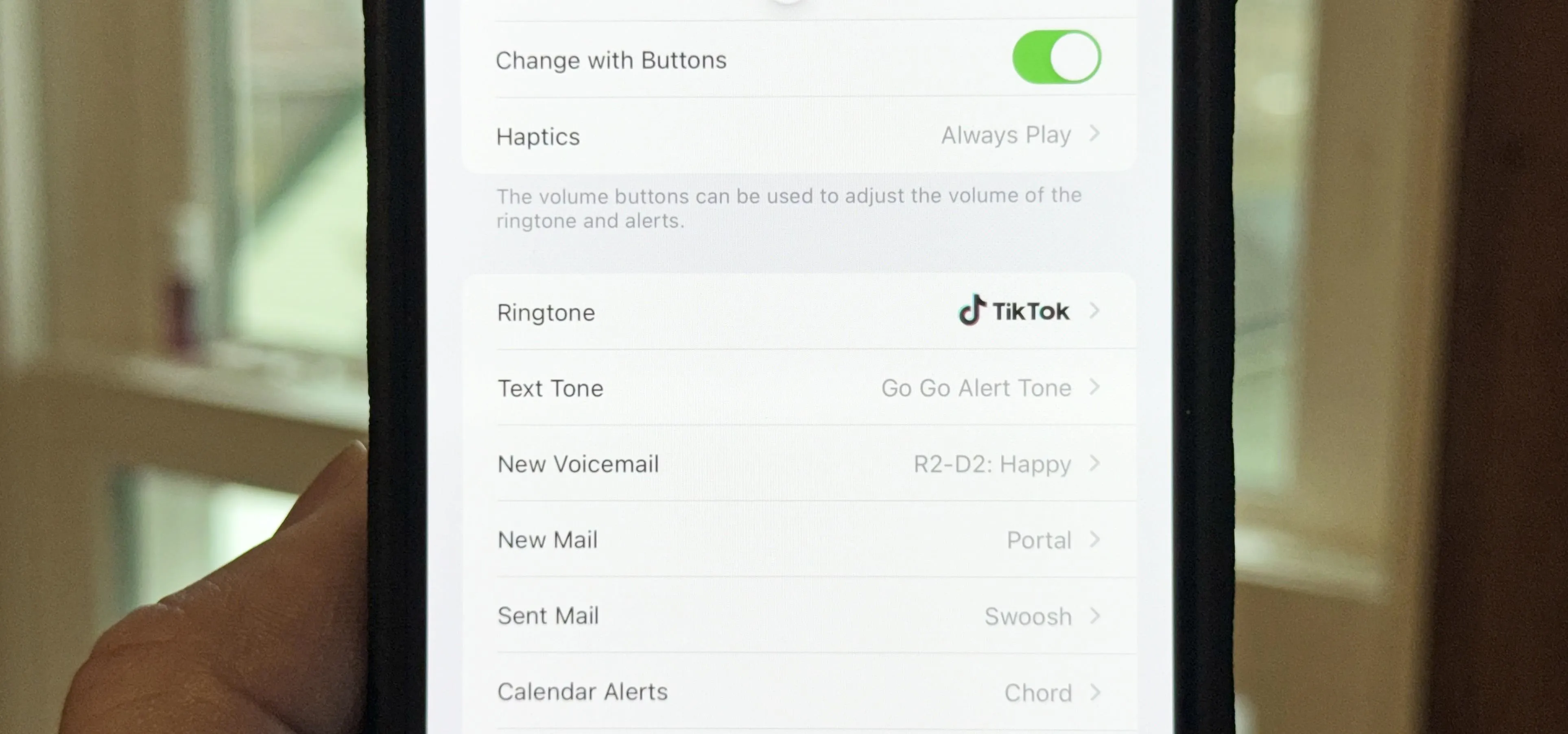

Music & Audio

Featured On WonderHowTo:

Augmented Reality

Featured On WonderHowTo:

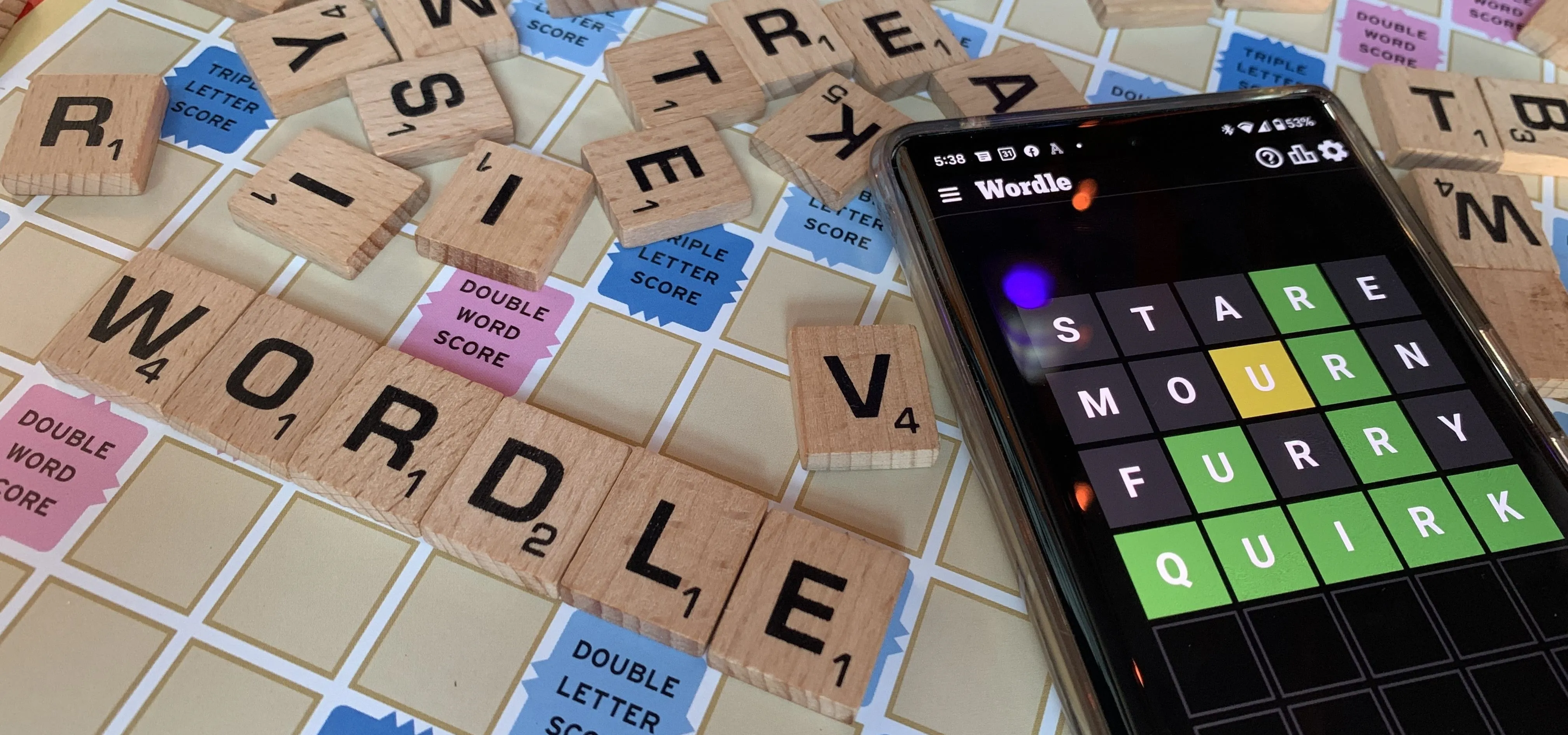

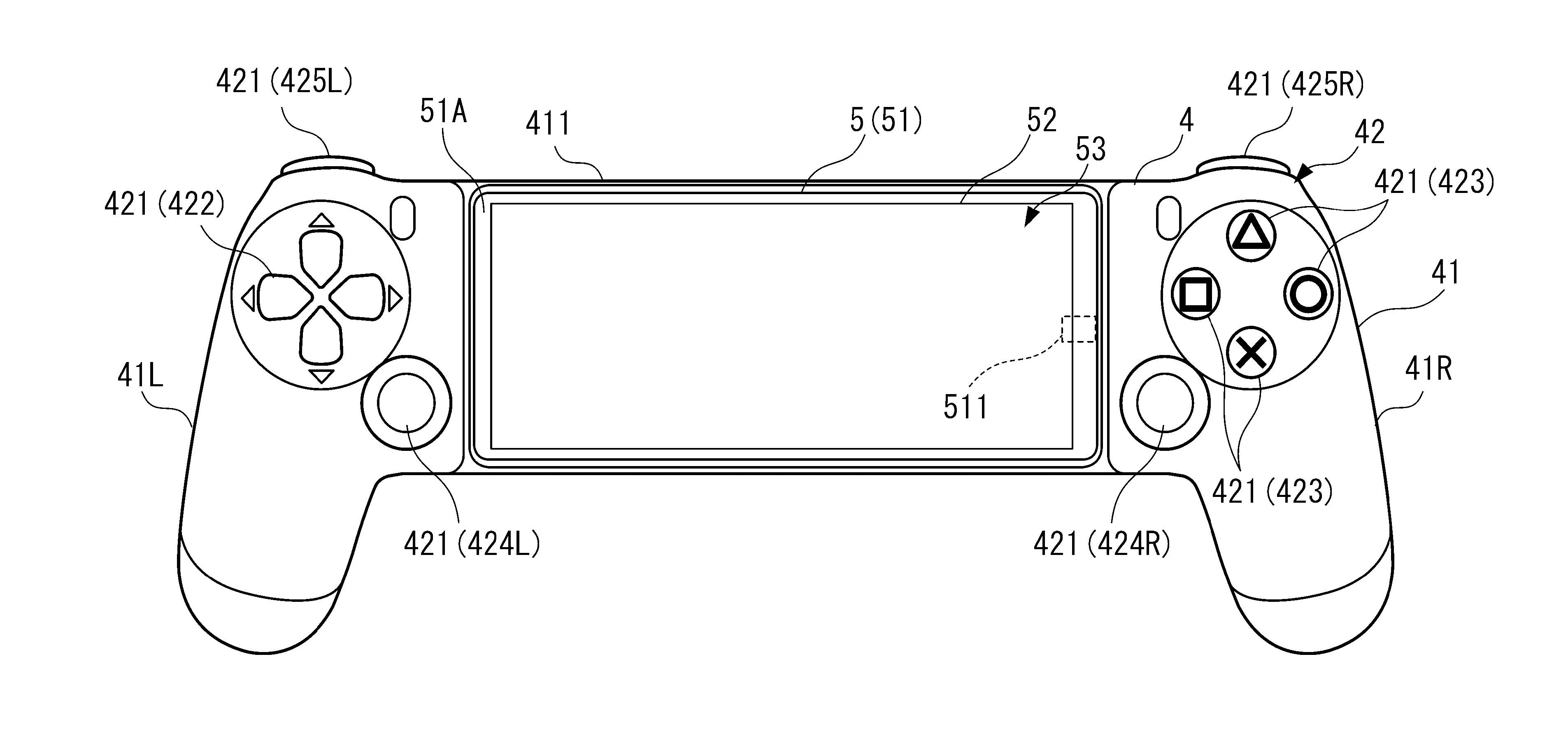

Gaming